Telescopic Butterfly Valve

manufacturer: Shanghai MeiYan Yi Pump & Valve Co., Ltd.

Eml: sales@1bengfa.com

Tel: +86 (21) 5640 2009

Mob: +86 138 1691 3072(WeChat Same Account)

product drawing

DS341X telescopic flange butterfly valves

The introduction

DS341X telescopic flange butterfly valve has automatic compensation for pipes thermal expansion and contraction and it is easy to install and disassemble. DS341X telescopic flange butterfly valve is the best device of adjusting flow and cutting off liquid in the pipelines of petroleum, chemical, electric power, paper making water supply and drainage, and municipal construction and other industries, which the temperature is below 425 ℃, and the nominal pressure is below 1.6Mpa. The main features are: 1, unique structure, flexible design, light weight, labor-saving, open and close quickly. 2, telescopic flange butterfly valve can compensate thermal expansion and contraction caused by the difference in temperature, and it is also easy for valve maintainence, replacement and installation. 3, the sealing parts of DS341X telescopic flange butterfly valve can be adjusted and replaced, and the sealing performance is reliable. DS341X telescopic flange butterfly valve manufacture standards: JB/T8527-97, GB / T 12238-89, Flange Standard: GB9113-2000, GB / T 17241. 6-1998, inspection standards: GB / T 13927-92.

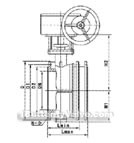

Dimensions & constructral diagram

DS341X telescopic flange butterfly valve constructral diagram(pic1)

Main technical parameter

| nominal diameter DN (mm) | 50~2000 | 50~1600 | ||

| nominal pressur PN(MPa) | 0.6 | 1.0 | 1.6 | |

| sealing test(MPa) | 0.66 | 1.1 | 1.76 | |

| intensity test(MPa) | 0.9 | 1.5 | 2.4 | |

| suitable temperature | soft-sealed | X:-40℃~90℃;Xf:-20℃~200℃ | ||

| hard-sealed | carbon steel :-29℃~425℃ stainless steel:-40℃~650℃ | |||

| applicable medium | water,air,natural gas,oil, and weak corrosive fluid | |||

| leakage rate | According with GB/T 13927-92 standard | |||

| drive mode | worm gear drive, electric, pneumatic, hydraulic | |||

The materials of main parts

| part name | materials |

| body | WCB, stainless steel, QT 450-10 |

| disc | WCB, stainless steel, QT 450-10 |

| shaft | 2Cr13 stainless steel |

| sealing ring | rubber |

| packing | flexible graphite |

The main external and connection dimensions of DS341X/F/H-6/10/16C,P,R(unit:mm)

| specifications | D | D1 | D2 | Lmax | Lmin | H1 | H2 | N-Фd |

| 100 | 220 | 180 | 156 | 216 | 174 | 110 | 170 | 8-Ф18 |

| 125 | 250 | 210 | 184 | 232 | 186 | 123 | 182 | 8-Ф18 |

| 150 | 285 | 240 | 211 | 239 | 194 | 140 | 210 | 8-Ф22 |

| 200 | 340 | 295 | 266 | 264 | 214 | 170 | 238 | 8-Ф22 |

| 250 | 395 | 350 | 319 | 296 | 235 | 195 | 270 | 12-Ф22 |

| 300 | 445 | 400 | 370 | 300 | 250 | 222 | 300 | 12-Ф22 |

| 350 | 505 | 460 | 429 | 320 | 270 | 252 | 330 | 16-Ф22 |

| 400 | 565 | 515 | 480 | 332 | 282 | 285 | 368 | 16-Ф26 |

| 450 | 615 | 565 | 530 | 355 | 305 | 310 | 402 | 20-Ф26 |

| 500 | 670 | 620 | 582 | 365 | 315 | 337 | 438 | 20-Ф30 |

| 600 | 780 | 725 | 682 | 420 | 340 | 393 | 490 | 24-Ф30 |

| 700 | 895 | 840 | 794 | 446 | 396 | 450 | 558 | 24-Ф33 |

| 800 | 1015 | 950 | 901 | 476 | 426 | 515 | 625 | 28-Ф33 |

| 900 | 1115 | 1050 | 1001 | 506 | 456 | 560 | 685 | 28-Ф33 |

| 1000 | 1230 | 1160 | 1112 | 516 | 466 | 610 | 750 | 28-Ф36 |

| 1200 | 1455 | 1380 | 1328 | 560 | 510 | 725 | 880 | 32-Ф39 |

| 1400 | 1675 | 1590 | 1530 | 590 | 540 | 840 | 987 | 36-Ф42 |

| 1600 | 1915 | 1820 | 1750 | 630 | 585 | 960 | 1158 | 40-Ф48 |

| 1800 | 2115 | 2020 | 1950 | 680 | 630 | 1060 | 1258 | 44-Ф48 |

| 2000 | 2325 | 2230 | 2150 | 730 | 680 | 1165 | 1365 | 48-Ф48 |