Lug Butterfly Valve

manufacturer: Shanghai MeiYan Yi Pump & Valve Co., Ltd.

Eml: sales@1bengfa.com

Tel: +86 (21) 5640 2009

Mob: +86 138 1691 3072(WeChat Same Account)

product drawing

Lug butterfly valves

Usage and features

D341H-10C API lug butterfly valve is a new high performance product developed by engineering and technical personnel. Its performance has been at the advanced level, and is widely used in low pressure, medium pressure, high pressure, steel metallurgy, petroleum, chemical, electric power and other industrial pipes, to cut off or adjust the media flow.

D341H-10C API lug butterfly valve adopts three-dimensional eccentric oblique cone-shaped seat sealing. The disc sealing formed bu using a new type of metal and elastic material stack, embedded installed in the disc in line with the seat. The use of disc swing pressed sealing, so the sealing face friction is small, the closed off has a function of the more closed more tightly, so that it has a reliable sealing performance, open to ensure the sealing face disengage completely and the sealing face without any injury.

The structural features of D341H-10C API lug butterfly valve exclude the shortcomings of other types butterfly valves of open more spaces can not be sealed, and it can be used under high temperature, overcomes other types of valves’ shortcomings of leaking easily due to thermal expansion used under high temperature.

The butterfly valve uses different sealing face materials according to the use of media requirements, in order to ensure sealing face wear resistance, erosion resistance, corrosion resistance, and a long service life.

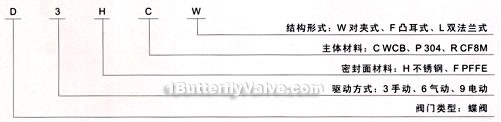

Model and organization method

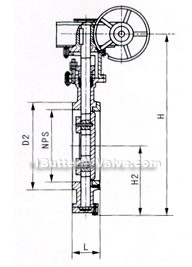

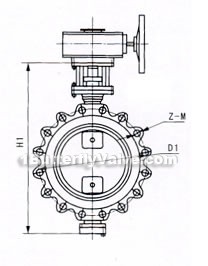

Dimensions & constructral diagram

Lug butterfly valve constructral diagram(pic1)

Lug butterfly valve constructral diagram(pic2)

Main technical parameters

| nominal diameter | Dn(in) | 2″-36″ | 2″-36″ |

| nominal pressure | PN(MPa) | 150Lb | 300Lb |

| test pressure(MPa) | intensity test | 3.0 | 7.5 |

| sealing test | 2.2 | 5.5 | |

| applicable medium | water,steam,oil,acid and alkali,seawater,etc | ||

| suitable temperature | -40~425℃ | ||

The materials of main parts

| part name | materials |

| body | WCB, CF8, CF8M |

| disc | WCB, CF8, CF8M |

| shaft lever | 304, 316, 1Cr13 |

| sealing ring | 316,304 |

| packing | flexible graphite,Fluoroplastics |

The main connection dimensions of D341H-10C API

| mo del |

in ch 〞 |

L | L1 | D | D1 | D2 | H2 | H1 | H | M | Z- d |

WT/Kgs | |||||||||

| mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | Wa fer type |

Fla nge type |

||||

| D 315 WF |

2 | 1.72 | 43 | 4.25 | 108 | 6.00 | 152 | 4.75 | 120.5 | 3.62 | 92 | 4.33 | 110 | 11.02 | 280 | 13.58 | 345 | M 18 |

4-19 | 9 | 20 |

| 3 | 1.93 | 49 | 4.50 | 114 | 7.50 | 190 | 6.00 | 152.5 | 5.00 | 127 | 4.92 | 125 | 12.40 | 315 | 14.96 | 380 | M 18 |

4-19 | 11 | 29 | |

| 4 | 2.20 | 56 | 5.00 | 127 | 9.00 | 229 | 7.50 | 190.5 | 6.19 | 157 | 5.70 | 145 | 13.78 | 350 | 16.34 | 415 | M 20 |

8-19 | 13 | 33 | |

| 5 | 2.50 | 64 | 5.50 | 140 | 10.00 | 254 | 8.50 | 216 | 7.32 | 186 | 6.50 | 165 | 15.35 | 390 | 17.91 | 455 | M 20 |

8-22 | 16 | 38 | |

| 6 | 2.75 | 70 | 5.50 | 140 | 11.00 | 279 | 9.50 | 241.5 | 8.50 | 216 | 6.89 | 175 | 17.91 | 455 | 21.45 | 545 | M 20 |

8-22 | 26 | 74 | |

| 8 | 2.80 | 71 | 5.90 | 150 | 13.50 | 343 | 11.75 | 298.5 | 10.62 | 270 | 8.26 | 210 | 20.67 | 252 | 24.21 | 615 | M 24 |

8-22 | 34 | 86 | |

| 10 | 3.00 | 76 | 6.30 | 160 | 16.00 | 406 | 14.25 | 362 | 12.75 | 324 | 9.84 | 250 | 23.81 | 605 | 27.36 | 695 | M 24 |

12-25 | 51 | 142 | |

| 12 | 3.38 | 86 | 4.00 | 178 | 19.00 | 483 | 17.00 | 432 | 15.00 | 381 | 11.24 | 285 | 28.74 | 730 | 32.78 | 830 | M 27 |

12-25 | 72 | 167 | |

| 14 | 3.63 | 92 | 4.20 | 190 | 21.00 | 533 | 18.75 | 476 | 16.25 | 413 | 12.60 | 320 | 31.50 | 800 | 35.43 | 900 | M 27 |

12-29 | 106 | 218 | |

| 16 | 4.00 | 102 | 8.5 | 216 | 23.50 | 597 | 21.25 | 540 | 18.50 | 470 | 13.98 | 355 | 34.25 | 840 | 38.58 | 980 | M 30 |

16-29 | 133 | 275 | |

| 18 | 4.50 | 114 | 8.74 | 222 | 25.00 | 635 | 22.75 | 578 | 21.00 | 533 | 14.96 | 380 | 36.22 | 920 | 40.55 | 1030 | M 30 |

16-32 | 176 | 315 | |

| 20 | 5.00 | 127 | 9.00 | 229 | 27.50 | 399 | 25.00 | 635 | 23.00 | 584 | 16.34 | 415 | 39.37 | 1000 | 43.70 | 1110 | M 33 |

20-32 | 190 | 395 | |

| 24 | 6.06 | 154 | 10.50 | 267 | 32.00 | 813 | 29.50 | 749.5 | 27.25 | 692 | 18.70 | 475 | 45.51 | 1155 | 51.37 | 1305 | M 33 |

20-35 | 394 | 580 | |

| 30 | 6.50 | 165 | 11.50 | 292 | 38.75 | 985 | 36.00 | 914 | 33.75 | 857 | 22.38 | 580 | 54.13 | 1375 | 60.03 | 1525 | M 39 |

28-35 | 476 | 717 | |

| 32 | 7.50 | 190 | 12.50 | 318 | 41.75 | 1060 | 38.50 | 978 | 36.00 | 814 | 24.80 | 630 | 56.50 | 1435 | 62.40 | 1585 | M 39 |

28-41 | 618 | 880 | |

| 36 | 8.00 | 203 | 13.00 | 330 | 46.00 | 1168 | 42.75 | 1085 | 40.25 | 1022 | 26.77 | 680 | 62.40 | 1585 | 69.48 | 1765 | M 20 |

32-41 | 762 | 1042 | |

| D 330 WF |

6 | 2.75 | 70 | 9.50 | 240 | 3.50 | 216 | 6.89 | 175 | 17.91 | 435 | 21.45 | 545 | M 20 |

8-22 | 28 | |||||

| 8 | 2.80 | 71 | 11.75 | 298 | 10.62 | 270 | 8.26 | 210 | 20.67 | 525 | 24.21 | 615 | M 24 |

8-22 | 36 | ||||||

| 10 | 3.00 | 76 | 14.25 | 362 | 12.75 | 324 | 9.84 | 250 | 23.81 | 605 | 27.36 | 695 | M 24 |

12-25 | 53 | ||||||

| 12 | 3.38 | 86 | 17.00 | 432 | 15.00 | 381 | 11.24 | 285 | 28.74 | 730 | 32.78 | 830 | M 27 |

12-25 | 74 | ||||||

| 14 | 3.63 | 92 | 18.25 | 476 | 16.25 | 413 | 12.64 | 320 | 31.50 | 800 | 35.43 | 900 | M 27 |

12-29 | 110 | ||||||

| 16 | 4.00 | 102 | 21.25 | 540 | 18.50 | 470 | 13.98 | 355 | 31.25 | 870 | 35.58 | 980 | M 30 |

16-29 | 138 | ||||||

| 18 | 4.50 | 114 | 22.75 | 578 | 21.00 | 533 | 14.96 | 380 | 36.22 | 920 | 40.55 | 1030 | M 30 |

16-32 | 180 | ||||||

| 20 | 5.00 | 127 | 25.00 | 635 | 23.00 | 584 | 16.34 | 415 | 39.37 | 1000 | 43.70 | 1110 | M 33 |

20-32 | 196 | ||||||

| 24 | 6.06 | 154 | 29.50 | 749 | 27.25 | 692 | 18.70 | 475 | 45.51 | 1156 | 51.37 | 1305 | M 33 |

20-35 | 400 | ||||||

| 30 | 6.50 | 165 | 36.00 | 914 | 33.75 | 857 | 22.38 | 580 | 54.13 | 1375 | 60.03 | 1525 | M 39 |

28-35 | 482 | ||||||

| 36 | 8.00 | 203 | 42.75 | 1085 | 40.25 | 1022 | 26.77 | 680 | 62.40 | 1585 | 69.48 | 1765 | M 18 |

32-42 | 468 | ||||||

| D 315 L |

2 | 1.72 | 43 | 4.25 | 108 | 6.50 | 165 | 5.00 | 127 | 3.62 | 92 | 4.33 | 110 | 11.02 | 280 | 13.58 | 345 | M 20 |

8-19 | 9 | 20 |

| 3 | 2.50 | 64 | 4.50 | 114 | 8.26 | 210 | 6.63 | 168 | 5.08 | 127 | 4.92 | 125 | 12.40 | 315 | 14.96 | 380 | M 20 |

8-22 | 12 | 29 | |

| 4 | 2.50 | 64 | 5.00 | 127 | 10.00 | 254 | 7.87 | 200 | 6.18 | 157 | 5.70 | 145 | 13.78 | 350 | 16.34 | 415 | M 20 |

8-22 | 15 | 35 | |

| 5 | 2.75 | 70 | 5.50 | 140 | 11.00 | 279 | 9.25 | 235 | 7.32 | 186 | 6.30 | 165 | 15.35 | 3920 | 17.91 | 455 | M 20 |

8-22 | 18 | 40 | |

| 6 | 3.00 | 76 | 8.30 | 210 | 12.50 | 318 | 10.63 | 270 | 8.50 | 216 | 6.89 | 175 | 17.91 | 455 | 21.45 | 545 | M 24 |

12-22 | 28 | 81 | |

| 8 | 3.50 | 89 | 9.05 | 230 | 15.00 | 381 | 13.00 | 330 | 10.62 | 270 | 8.26 | 210 | 20.37 | 525 | 24.21 | 615 | M 27 |

12-26 | 37 | 94 | |

| 10 | 4.50 | 114 | 9.84 | 250 | 17.50 | 445 | 15.24 | 387 | 12.75 | 324 | 9.84 | 256 | 23.81 | 605 | 27.36 | 695 | M 30 |

16-29 | 56 | 156 | |

| 12 | 4.50 | 114 | 10.62 | 270 | 20.50 | 521 | 17.76 | 451 | 15.00 | 381 | 11.24 | 285 | 28.74 | 730 | 32.78 | 830 | M 30 |

16-32 | 79 | 183 | |

| 14 | 5.00 | 127 | 10.62 | 270 | 23.00 | 584 | 20.24 | 514 | 16.26 | 413 | 12.60 | 320 | 31.50 | 800 | 35.43 | 900 | M 33 |

20-32 | 116 | 239 | |

| 16 | 5.50 | 140 | 12.20 | 310 | 25.50 | 648 | 12.50 | 571 | 18.50 | 470 | 13.98 | 355 | 34.25 | 870 | 38.58 | 980 | M 33 |

20-35 | 146 | 302 | |

| 18 | 5.98 | 152 | 13.00 | 330 | 28.00 | 711 | 24.72 | 628 | 21.00 | 533 | 14.96 | 380 | 36.22 | 920 | 40.55 | 1030 | M 33 |

24-35 | 193 | 346 | |

| 20 | 5.98 | 152 | 13.80 | 350 | 30.50 | 775 | 27.00 | 686 | 23.00 | 584 | 16.34 | 415 | 39.37 | 1000 | 43.70 | 1110 | M 33 |

24-35 | 209 | 434 | |

| 24 | 7.00 | 178 | 15.35 | 390 | 36.00 | 914 | 32.00 | 813 | 27.24 | 692 | 18.70 | 475 | 45.51 | 1156 | 51.37 | 1305 | M 39 |

24-41 | 433 | 638 | |

| 30 | 9.01 | 229 | 17.71 | 450 | 43.00 | 1092 | 39.25 | 997 | 27.69 | 703 | 22.38 | 580 | 54.13 | 1375 | 60.03 | 1525 | M 45 |

28-49 | 523 | 788 | |

| 36 | 9.88 | 241 | 20.07 | 510 | 50.00 | 1270 | 46.00 | 1168 | 34.88 | 886 | 26.77 | 680 | 62.40 | 1858 | 69.48 | 1765 | M 50 |

32-53 | 838 | 1146 | |

| D 330 L |

6 | 3.00 | 76 | 10.63 | 270 | 8.50 | 216 | 6.89 | 175 | 17.01 | 455 | 21.45 | 545 | M 20 |

12-22 | 29 | |||||

| 8 | 6.50 | 89 | 13.00 | 330 | 10.62 | 270 | 8.26 | 210 | 20.67 | 525 | 24.21 | 615 | M 24 |

12-36 | 38 | ||||||

| 10 | 4.50 | 114 | 15.24 | 387 | 12.75 | 324 | 9.84 | 250 | 23.81 | 605 | 28.36 | 695 | M 27 |

16-29 | 58 | ||||||

| 12 | 4.50 | 114 | 17.76 | 451 | 15.00 | 381 | 11.24 | 285 | 28.74 | 730 | 32.78 | 830 | M 30 |

16-32 | 81 | ||||||

| 14 | 5.00 | 127 | 20.24 | 514 | 16.26 | 413 | 12.60 | 320 | 31.50 | 800 | 35.43 | 900 | M 30 |

20-32 | 119 | ||||||

| 16 | 5.50 | 140 | 22.30 | 591 | 18.50 | 470 | 13.98 | 355 | 34.25 | 870 | 38.58 | 980 | M 33 |

24-35 | 149 | ||||||

| 18 | 5.98 | 152 | 24.72 | 628 | 21.00 | 533 | 14.96 | 380 | 36.22 | 920 | 40.55 | 1030 | M 33 |

24-35 | 198 | ||||||

| 20 | 5.98 | 152 | 27.00 | 686 | 23.00 | 584 | 16.34 | 415 | 39.37 | 1000 | 43.70 | 1110 | M 33 |

24-35 | 215 | ||||||

| 24 | 7.00 | 178 | 32.00 | 813 | 27.24 | 692 | 18.70 | 475 | 45.51 | 1156 | 51.37 | 1305 | M 39 |

24-41 | 436 | ||||||

| 30 | 9.01 | 229 | 39.25 | 991 | 27.69 | 703 | 22.38 | 580 | 54.13 | 1375 | 60.06 | 1525 | M 45 |

28-49 | 528 | ||||||

| 36 | 9.88 | 241 | 46.00 | 1168 | 34.88 | 886 | 26.77 | 680 | 62.40 | 1585 | 69.48 | 1765 | M 50 |

32-52 | 843 | ||||||