Hydraulic Control Check Butterfly Valve

manufacturer: Shanghai MeiYan Yi Pump & Valve Co., Ltd.

Eml: sales@1bengfa.com

Tel: +86 (21) 5640 2009

Mob: +86 138 1691 3072(WeChat Same Account)

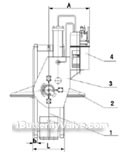

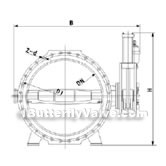

product drawing

Hydraulic control check butterfly valves

Usages and features of product

HD7Q41X full hydraulic control check butterfly valve is used in the outlet pipes of the water medium. It is used to prevent and reduce the back flow of piping system medium and the excessive water hammer, in order to protect the pipe system. and its function is based on one valve on behalf of two valves (in the traditional pipeline designs, it is gate valve matched check valve or butterfly valve matched check valve). The main features are: 1, The control parts of HD7Q41X full hydraulic control check butterfly valve use full hydraulic control forms, replace the heavy hammer by accumulator, reduce the energy loss, simplify the transmission mechanism, occupy small space, and similar with the general valves. The installation is easy, you can install left and right horizontal, or vertical. 2, HD7Q41X full hydraulic control check butterfly valve is installed after the pump, can replace the gate valve (butterfly valve) and the check valve. And the flow resistance coefficient is small, oversized butterfly valve flow resistance coefficient is only slightly higher than the gate valve. Therefore, this valve is energy-saving product. 3, When closed, the fast and slow switches time and switch angles can be adjusted according to the characteristics of pipeline system or customers’ requirements, so as to achieve the elimination or decrease of water hammer and protect the system. 4, if all the limit switches use inductive proximity switches, remove the hydraulic station, and the protection level is up to IP67.

Dimensions & constructral diagram

Hydraulic control check butterfly valve constructral diagram(pic1)

Hydraulic control check butterfly valve constructral diagram(pic2)

The main technical parameters

| nominal diameter(mm) | 1400-2400 | 1200-2400 | 500-2400 | 500-2400 | 500-1600 | |

| nominal pressure(MPa) | 0.25 | 0.6 | 1.0 | 1.6 | 2.5 | |

| test pressure (MPa) | intensity test | 0.375 | 0.9 | 1.5 | 2.4 | 3.75 |

| sealing test | 0.275 | 0.66 | 1.1 | 1.76 | 2.75 | |

| applicable medium | water | |||||

| suitable temperature(℃) | ≤80℃ | |||||

| medium flow | 3m/s | |||||

The materials of main parts and execution standard

| part name | materials | manufacture standard | JB/T8527-97、GB/T12238-89 |

| body | grey cast iron,ductile cast iron,carbon steel | flange standard | GB/T17241.6-1998、GB2555-2556-81 |

| disc | grey cast iron,ductile cast iron,cast steel | face to face dimension standard | GB/T12221-89 |

| shaft | stainless steel | test standard | GB/T 13927-92 |

| sealing ring | Stainless steel, NBR | ||

| packing | NBR |

The main external and connection dimensions of HD7Q41X(unit:mm)

| DN | PN | D | D1 | b | L | A | B | H |

| 500 | 1.0 | 670 | 620 | 43 | 229 | 720 | 1650 | 1360 |

| 600 | 1.0 | 780 | 725 | 48 | 267 | 720 | 1730 | 1390 |

| 700 | 1.0 | 895 | 840 | 54 | 292 | 720 | 1800 | 1445 |

| 800 | 1.0 | 1015 | 950 | 58 | 318 | 720 | 1870 | 1485 |

| 900 | 1.0 | 1115 | 1050 | 61 | 330 | 720 | 2070 | 1865 |

| 1000 | 1.0 | 1230 | 1160 | 67 | 410 | 755 | 2165 | 1930 |

| 1200 | 1.0 | 1455 | 1380 | 65 | 470 | 905 | 2265 | 2030 |

| 1400 | 1.0 | 1675 | 1590 | 68 | 530 | 905 | 2665 | 2270 |

| 1200 | 0.6 | 1405 | 1340 | 65 | 470 | 755 | 2365 | 2025 |

| 1400 | 0.6 | 1630 | 1560 | 68 | 530 | 755 | 2665 | 2270 |

| 1600 | 0.6/0.25 | 1830 | 1760 | 68 | 600 | 905 | 2940 | 2380 |

| 1800 | 0.6/0.25 | 2045 | 1970 | 70 | 670 | 905 | 3325 | 2470 |

| 2000 | 0.25 | 2265 | 2180 | 54 | 760 | 905 | 3660 | 2370 |

| 2200 | 0.25 | 2475 | 2390 | 60 | 840 | 1123 | 4325 | 2940 |

| 2400 | 0.25 | 2685 | 2600 | 62 | 910 | 1123 | 4530 | 3000 |