Electric Hard-sealed Flange Butterfly Valve

manufacturer: Shanghai MeiYan Yi Pump & Valve Co., Ltd.

Eml: sales@1bengfa.com

Tel: +86 (21) 5640 2009

Mob: +86 138 1691 3072(WeChat Same Account)

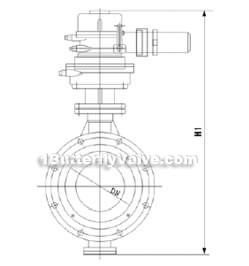

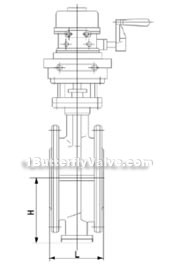

product drawing

Electric hard-sealed flange butterfly valves

Technical performance

D943H electric hard-sealed flange butterfly valve uses three-eccentric sealing structure, seat and disc almost are no wear and tear, with the more closed more tight sealing function. The sealing ring made of stainless steel with dual advantages of metal hard-sealed and flexible sealing. In terms of low temperature and high temperature conditions, the D943H electric hard-sealed flange butterfly valve manufactured by Shanghai Fengqi Industry Development Co.,ltd has excellent sealing performance and long service life. The disc sealing face of D943H electric hard-sealed flange butterfly valve manufactured by Shanghai Fengqi Industry Development Co.,ltd, uses cobalt-based alloy welding. The sealing face is wear resistance and has a long service life.Oversized disc adopts lattice structure, has high strength, over-current area, small flow resistance. The valve also has bi-directional sealing capabilities, it can be installed in any direction without restricted by media flow and affected by position and space. The drives can be installed multi-bit ( rotated 90° or 180°), easy for customers use.

Dimensions & constructral diagram

Electric hard-sealed flange butterfly valve constructral diagram(pic1)

Electric hard-sealed flange butterfly valve constructral diagram(pic2)

The main technical parameters

| nominal diameterDN(mm) | 50~2000 | |||

| nominal pressurePN(MPa) | 0.6 | 1.0 | 1.6 | 2.5 |

| sealing test(MPa) | 0.66 | 1.1 | 1.76 | 2.75 |

| intensity test(MPa) | 0.9 | 1.5 | 2.4 | 3.75 |

| suitable temperature | Carbon steel:-29℃~425℃ stainless steel:-40℃~650℃ | |||

| applicable medium | water,air,natural gas,oil, and weak corrosive fluid | |||

| leakage rate | According with GB/T13927-92 standard | |||

| drive mode | worm gear drive,electric,pneumatic,hydraulic | |||

The materials of main parts

| part name | materials |

| body | WCB, alloy steel, stainless steel, QT4500 |

| disc | WCB, alloy steel, stainless steel, QT4500 |

| shaft | 2Cr13 stainless steel, alloy steel |

| sealing ring | stainless ring |

| packing | flexible graphite |

Standard

| manufacture standard | JB/T 8527-97 |

| flange standard | GB9113-2000 |

| face to face dimension standard | GB12221-89 |

| test standard | GB/T 13927-92 |

The main external and connection dimensions of D943H-10/16

| nominal diameter (DN)(mm) | main dimensions | flange dimensions and bolt specification | ||||||||||

| 1.0MPa | 1.6MPa | 2.5MPa | ||||||||||

| L | H | H1 | D | D1 | n-Фd | D | D1 | n-Фd | D | D1 | n-Фd | |

| 50 | 108 | 530 | 112 | 165 | 125 | 4-18 | 165 | 125 | 4-18 | 165 | 125 | 4-18 |

| 65 | 112 | 530 | 115 | 185 | 145 | 4-18 | 185 | 145 | 4-18 | 185 | 145 | 8-18 |

| 80 | 114 | 565 | 120 | 200 | 160 | 4-18 | 200 | 160 | 8-18 | 200 | 160 | 8-18 |

| 100 | 127 | 600 | 138 | 220 | 180 | 8-18 | 220 | 180 | 8-18 | 235 | 190 | 8-22 |

| 125 | 140 | 640 | 164 | 250 | 210 | 8-18 | 250 | 210 | 8-18 | 270 | 220 | 8-26 |

| 150 | 140 | 705 | 175 | 285 | 240 | 8-22 | 285 | 240 | 8-22 | 300 | 250 | 8-26 |

| 200 | 152 | 775 | 200 | 340 | 295 | 8-22 | 340 | 295 | 12-22 | 360 | 310 | 12-26 |

| 250 | 165 | 945 | 243 | 395 | 350 | 12-22 | 405 | 355 | 12-26 | 425 | 370 | 12-30 |

| 300 | 178 | 1070 | 250 | 445 | 400 | 12-22 | 460 | 410 | 12-26 | 485 | 430 | 16-30 |

| 350 | 190 | 1140 | 280 | 505 | 460 | 16-22 | 520 | 470 | 16-26 | 555 | 490 | 16-33 |

| 400 | 216 | 1210 | 305 | 565 | 515 | 16-26 | 580 | 525 | 16-30 | 620 | 550 | 16-36 |

| 450 | 222 | 1335 | 350 | 615 | 565 | 20-26 | 640 | 585 | 20-30 | 670 | 600 | 20-36 |

| 500 | 229 | 1415 | 380 | 670 | 620 | 20-26 | 715 | 650 | 20-33 | 730 | 660 | 20-36 |

| 600 | 267 | 1605 | 445 | 780 | 725 | 20-30 | 840 | 770 | 20-36 | 845 | 770 | 20-39 |

| 700 | 292 | 1844 | 480 | 895 | 840 | 24-33 | 910 | 840 | 24-36 | 960 | 875 | 24-42 |

| 800 | 318 | 2040 | 530 | 1015 | 950 | 24-33 | 1025 | 950 | 24-39 | 1085 | 990 | 24-48 |

| 900 | 330 | 2255 | 580 | 1115 | 1050 | 28-33 | 1125 | 1050 | 28-39 | 1185 | 1090 | 28-48 |

| 1000 | 410 | 2380 | 650 | 1230 | 1160 | 28-36 | 1255 | 1170 | 28-42 | 1320 | 1210 | 28-56 |

| 1200 | 470 | 2640 | 760 | 1455 | 1380 | 32-39 | 1485 | 1390 | 32-48 | 1530 | 1420 | 32-56 |

| 1400 | 530 | 2886 | 850 | 1675 | 1590 | 36-42 | 1685 | 1590 | 36-48 | 1755 | 1640 | 36-62 |

| 1600 | 600 | 3156 | 1030 | 1915 | 1820 | 40-48 | 1930 | 1820 | 40-56 | 1975 | 1860 | 40-62 |

| 1800 | 670 | 3421 | 1230 | 2115 | 2020 | 44-48 | 2130 | 2020 | 44-56 | 2195 | 2070 | 44-70 |

| 2000 | 760 | 3685 | 1350 | 2325 | 2230 | 48-48 | 2345 | 2230 | 48-62 | 2425 | 2300 | 48-70 |