Butterfly Buffering Check Valve

manufacturer: Shanghai MeiYan Yi Pump & Valve Co., Ltd.

Eml: sales@1bengfa.com

Tel: +86 (21) 5640 2009

Mob: +86 138 1691 3072(WeChat Same Account)

product drawing

Butterfly buffering check valves

The introduction and features

HH47 butterfly buffering check valve uses sealing three accentric and large secondary accentric of disc to ensure zero leakage after closure, uses small damping of opening valve to ensure a smooth opening of disc, uses quick and slow two stages closure to ensure the closing speed, meanwhile buffer effectively and eliminate the impact of water hammer. The main features are: 1, HH47 butterfly buffering check valve is suitable for oversized pipeline of water or steam medium, plays the role of check, and can achieve qucik and slow off, prevent water hammer impact effectively. 2, three eccentric sealing structure ensures zero leakage, the open action is steady, the flow resistance is small; 3, the quick off stage almost has no resistance, and slow off stage buffers steady, with no water hammer, non-impulsive noise. 4, sealing three accentric and large secondary accentric of disc structure, when opening the sealing part, it is separated; when closing the contacts, it is sealed. It reduces the sealing face’s abrasion effectively and prolong the service life.

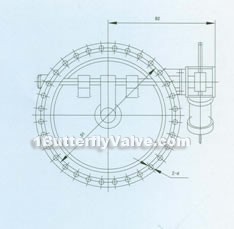

Dimensions & constructral diagram

Butterfly buffering check valve constructral diagram(pic1)

Butterfly buffering check valve constructral diagram(pic2)

Main technical diameter

| nominal pressure | PN | ANSI | |||

| 0.25~6.4MPa | 150LB-300LB | ||||

| nominal diameter | PN2.5(DN300~DN2000),PN6(DN300~DN2000),PN10(DN300~DN1600),PN16(DN300~1000)PN25,PN40,PN64(DN300~DN800) | ||||

| intensity test | 1.5 times | ||||

| sealing test | 1.1 times | ||||

| body materials | grey cast iron | ductile cast iron | Carbon steel | alloy steel | stainless steel P/R |

| working temperature | 0~150℃ | -15~300℃ | -29~425℃ | -29~530℃ | -196~600℃ |

| applicable medium | water,steam,gas,oil,etc | water, steam, gas, oil,etc | water, steam, gas, oil,etc | water, steam, gas, oil,etc | acetic acid,nitric acid |

Implement standard

| design and manufacture | flange connection | face to face dimensions | pressure test |

| GB12236 | GB17241.6、GB9113 | GB12221 | ZBJ16006 |

| ANSI B16.34 | ANSI B16.5 or MSS-SP-44CL | API1609 | API1598 |

The main external and connection dimensions of HH47

| DN | L | B1 | B2 | flange connection dimensions of different nominal pressure levels | remarks | ||||||||

| 0.25 | 0.6 | 1.0 | 1.6 | 2.5 | 4.0 | 6.4 | 150LB | 300LB | |||||

| 300 | 178 | 1000 | 809 | GB/T17241.6 | GB/T9113 | ANSI B16.5 MSS-SP-44CL | |||||||

| 350 | 190 | 1000 | 838 | ||||||||||

| 400 | 216 | 1000 | 862 | ||||||||||

| 450 | 222 | 1000 | 887 | ||||||||||

| 500 | 229 | 1465 | 905 | ||||||||||

| 600 | 267 | 1465 | 960 | ||||||||||

| 700 | 292 | 1465 | 1015 | ||||||||||

| 800 | 318 | 1465 | 1070 | ||||||||||

| 900 | 330 | 1465 | 1120 | ||||||||||

| 1000 | 410 | 1465 | 1170 | ||||||||||

| 1200 | 470 | 1465 | 1285 | ||||||||||

| 1400 | 530 | 1465 | 1400 | ||||||||||

| 1600 | 600 | 1725 | 1525 | ||||||||||

| 1800 | 670 | 1725 | 1650 | ||||||||||

| 2000 | 760 | 1725 | 1889 | ||||||||||