Anti-condensation Al-alloy Diecasting Butterfly Valve

Structural features

Ultra-light aluminum alloy body, the troque is small, easy to operate and install, prevent the rust.

It is applied to air-conditioning, industrial water treatment equipments, has a strong anti-condensation funtion. Aluminum alloy diecasting body prevents the rust.

F500 series of butterfly valve play a superior function in the prevention of condensation. The unique multi-level asymptotic contact seat is developed by the use of technology and experience accumulated over the years, and the F500 series of butterfly valve synthesize a number of other technologies, are being replaced other valves in more and more areas, with a simple construction and long service life characteristics.

excellent and long-lasting sealing performance.

Some designs of multi-level progressive-contact seat make the disc contact with the seat gradually during the close process. It ensures a good sealing performance and reduces the unnecessary torque, thus extending the service life of the seat

the reduction of torque achieve the light and miniaturization of the drive devices.

the unique stem sealing ring can prevent the fluid leakage.

the seats of different materials can be adapt to different working conditions, with good anti-corrosive and sealing performance.

Spherical disc trajectory makes the valve rotating flexibly and freely.

The disc is processed by a complete ball, each part of the sealing face is the part of the sphere. There is no exception even the axial sealing face of the top and bottom of disc. This sealing face is still smooth when sealing, in spite of contacting. So the torque is reduced, the sealing performance improves, especially the friction of axial sealing part is reduced. Using this technology, the seat service life is increased threefold.

Standard parameters

| type | F500 | Face to face dimension | JIS GB API |

| Nominal diameter | 40-300mm | Top flange standard | GB ISO 5211 |

| Flange specification | JIS ANSI GB | materials | body:aluminum alloy |

| Max working temperature | 1.0MPa | Disc: stainless steel | |

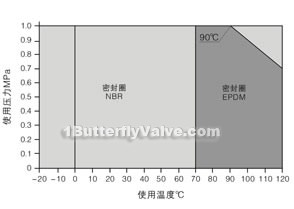

| Temperature scope | 0-120℃ EPDM 0-70℃ NBR | Sealing ring:EPDM(MBR) | |

| Leak test pressure | 1.1MPa | spray paint specification | polyester powder paint |

| Body test perssure | 1.5MPa | ||

| Drive mode | Handle,gear,cylinder,electric |

Anti-condensation al-alloy diecasting butterfly valve constructral diagram(pic7)

Anti-condensation al-alloy diecasting butterfly valve constructral diagram(pic8)

Dimensions & constructral diagram

Anti-condensation al-alloy diecasting butterfly valve constructral diagram(pic1)

Anti-condensation al-alloy diecasting butterfly valve constructral diagram(pic2)

Anti-condensation al-alloy diecasting butterfly valve constructral diagram(pic3)

Anti-condensation al-alloy diecasting butterfly valve constructral diagram(pic4)

Anti-condensation al-alloy diecasting butterfly valve constructral diagram(pic5)

Anti-condensation al-alloy diecasting butterfly valve constructral diagram(pic6)

The manual external and connection dimensions and weight

| specification | dimensions (mm) | weight (kg) | ||||||||

| mm | inch | d | L | H1 | H2 | H3 | L1 | L2 | D1 | |

| 40 | 11/2" | 42 | 33 | 70 | 145 | 51 | 47 | 68 | 250 | 1.4 |

| 50 | 2" | 52 | 43 | 82 | 145 | 51 | 47 | 68 | 250 | 1.7 |

| 65 | 21/2" | 67 | 46 | 90 | 157 | 51 | 47 | 68 | 250 | 2.1 |

| 80 | 3" | 80 | 46 | 99 | 165 | 51 | 47 | 68 | 250 | 2.3 |

| 100 | 4" | 102 | 52 | 112 | 183 | 51 | 47 | 68 | 250 | 2.8 |

| 125 | 5" | 126 | 56 | 132 | 196 | 60 | 63 | 86 | 330 | 4.8 |

| 150 | 6" | 150 | 56 | 146 | 214 | 60 | 63 | 86 | 330 | 6.0 |

Turbine external and connection dimensions and weight

| specification | dimensions (mm) | weight (kg) | ||||||||||

| mm | d | L | H1 | H2 | H3 | L1 | L2 | L3 | S | D1 | ||

| 40 | 11/2" | 42 | 33 | 70 | 145 | 168 | 35 | 35 | 56 | 132 | 100 | 2.0 |

| 50 | 2" | 52 | 43 | 82 | 145 | 168 | 35 | 35 | 56 | 132 | 100 | 2.3 |

| 65 | 21/2" | 67 | 46 | 90 | 157 | 180 | 35 | 35 | 56 | 132 | 100 | 2.7 |

| 80 | 3" | 80 | 46 | 99 | 165 | 188 | 35 | 35 | 56 | 132 | 100 | 2.9 |

| 100 | 4" | 102 | 52 | 112 | 183 | 206 | 41 | 39 | 68 | 132 | 100 | 3.4 |

| 125 | 5" | 126 | 56 | 132 | 196 | 220 | 58 | 48 | 89 | 149 | 140 | 5.8 |

| 150 | 6" | 150 | 56 | 146 | 214 | 238 | 58 | 48 | 89 | 149 | 140 | 7.4 |

| 200 | 8" | 199 | 60 | 188 | 241 | 272 | 58 | 48 | 89 | 149 | 140 | 9.6 |

| 250 | 10" | 248 | 68 | 220 | 320 | 367 | 67 | 61 | 97 | 200 | 200 | 21.5 |

| 300 | 12" | 297 | 78 | 255 | 355 | 402 | 67 | 63 | 97 | 200 | 200 | 31.0 |